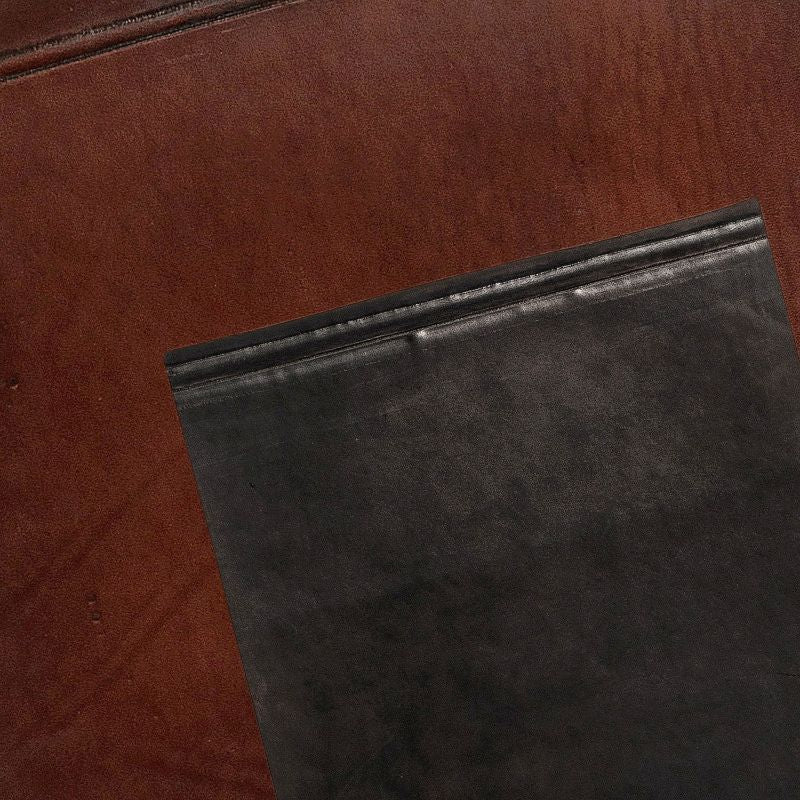

Full-grain vegetable-tanned aniline-finished stretched butt for stirrups and grith straps

Our vegetable-tanned stretched leather combines robustness and aesthetics with high resistance to elongation!

Features of Stretched Niagara leather :

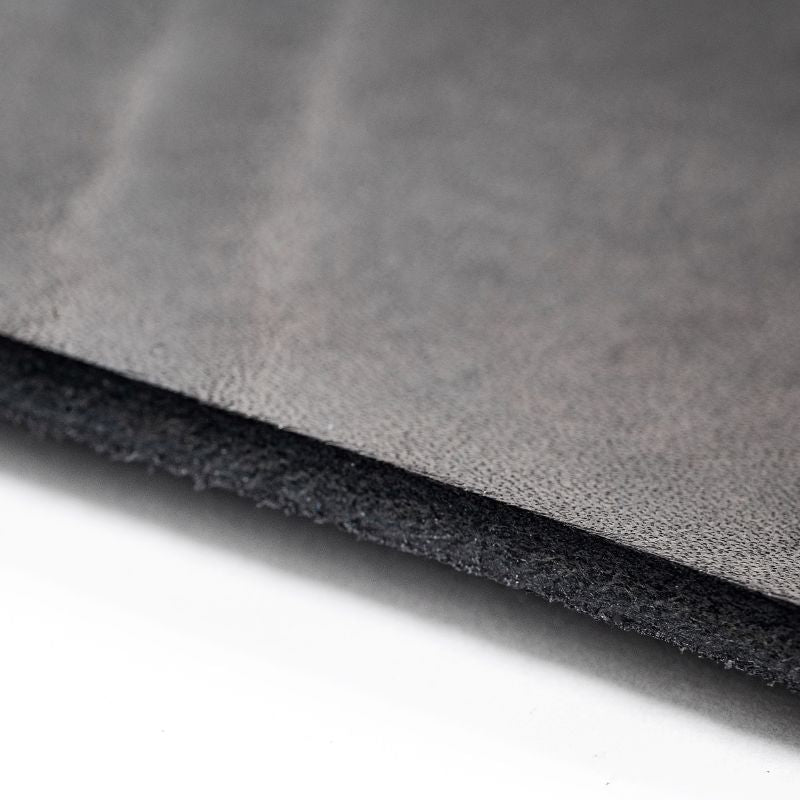

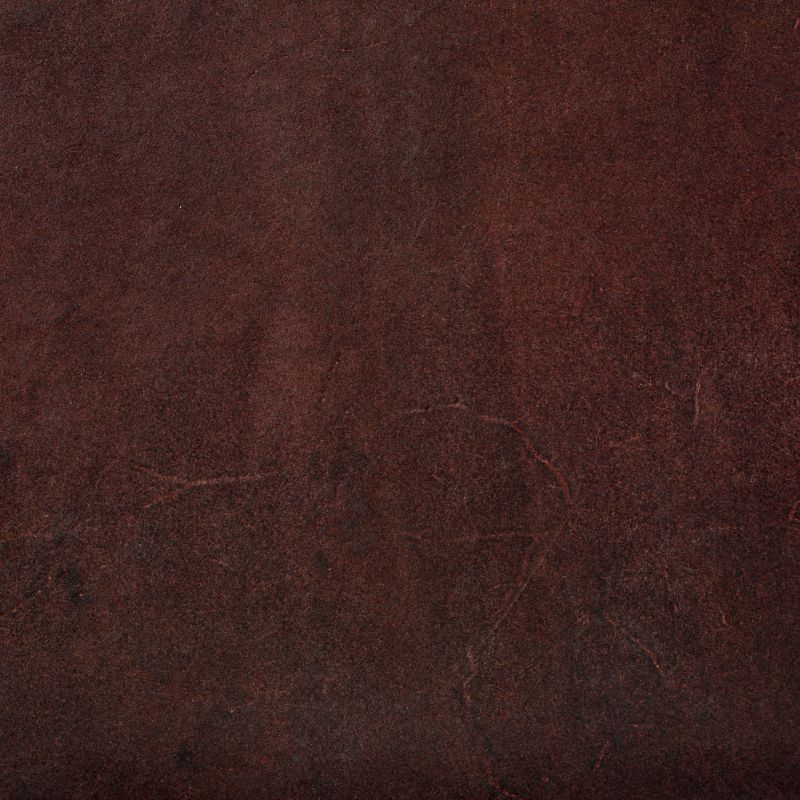

Stretched Niagara saddle leather is the leather for horse saddle stirrups and grith straps. Niagara stretched leather is a full-grain unpressed, uncorrected, smooth grain leather. It is a vegetable-tanned leather that is reworked wet and positioned on frames. Under tension, it minimizes its elasticity and elongation, and increases its absorption of direct stress without altering its tensile strength. This leather benefits from a aniline finish which preserves the natural appearance of the leather. The aniline finish consists of a thin, transparent layer that does not alter the texture of the leather. Stretched Niagara leather is available in Black and Chocolate aniline finishes. It is heart-fed in a tallow bath (a mixture of paraffin and beef fat), more commonly known as "tallow leather". This fat-bath feeding makes for easier cutting and working, as well as greater resistance to water. Tallow provides maintenance-free leather, as the grease is constantly applied to the surface of the leather, giving it the nourishment it needs and an excellent patina. Thanks to this nourishment, Niagara saddle leather is highly resistant to outdoor use, rejecting any external disturbance (water / salty environment). This makes Niagara saddle leather suitable for intensive wear and tear, such as in the equestrian sector. We guarantee an elongation of the leather over 1000 stretching cycles at 75 Kg of less than 10%. In addition, a 25mm wide, 4.5mm thick strap has a breaking strength of over 300 Kg.

Origin and traceability of Stretched Niagara leather :

Stretched Niagara leather comes from targeted beef or bull farms originating in France, Germany, Spain or Italy. To ensure the quality of the leather used in its production, Radermecker Tannery has set up a leather traceability process . The hides are marked 3 times with 3 identifiers at each stage: on receipt of the hides, enabling traceability of the origin of the hides; during the tanning process; during the finishing process.

Uses of Stretched Niagara leather :

Stretched Niagara leather is used to make stirrups and grith straps for horse saddles.

Dimensions and hide area of Stretched Niagara leather :

Stretched Niagara leather is one-third butt. The butt is one of the thickest and firmest hide areas. The sides, shoulder and all extremities have been removed. The butt is considered the noblest part of the leather. This area has no stretching and can therefore be cut in any direction. This area is used in particular for parts that need more resistance. We offer 2 sizes:

- Length 130cm - surface from 0.50 to 0.70m² with a minimum length of 130cm and a width greater than 35cm.

- Length 150cm - surface from 0.71 to 0.90m² with a minimum length of 150cm and a width greater than 35cm.

In the "Guaranteed dimensions" tab above, you'll find an explanatory diagram of the "third of butt" hide area and the corresponding guaranteed dimensions.

Care instructions of Stretched Niagara leather :

For care of your leathers, we recommend that you: pay particular attention to exposure to light, which can alter the color of your leathers; always dust your leathers with a dry cloth before applying a specific treatment. In case of contact with water, let your leathers dry naturally, at room temperature, without any additional heat source.

For the care of Niagara saddle leather, this leather is suitable for anyone who doesn't take the time to maintain their leather. It can live without maintenance, but you can also feed leather with a dust film. Thanks to tallow bath feeding, the fat is impregnated throughout the entire thickness of the stretched Niagara saddle leather, so there's no need to feed over time. Food can be applied to the grain to ensure its greasy appearance or to accelerate the leather's patina. This care of the grain ensures a longer life. Our Niagara saddle leather is moisture-resistant. Simply leave to dry at room temperature to regain its appearance. Because it is fed in a tallow bath (grease), a whitish film of paraffin can form on temperature shocks. Simply rub it off.