Leather was already used in prehistoric times as a basis for clothing, but nowadays the variety of leathers is greater.

Today, the modern techniques used by the leather industry allow for an innumerable variety of leathers. From the most classic to the most original, the leathers used in saddlery and leather goods allow a wide range of creation.

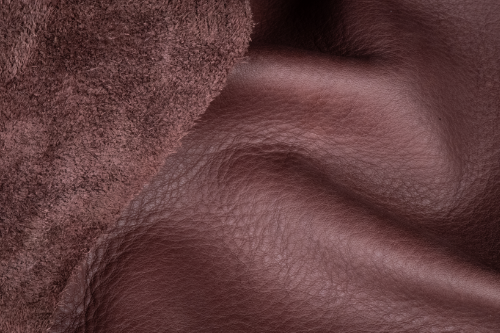

Before explaining the different types and names of leather, it is important to remember that there are two sides to leather: the grain, the outer part "hair side"; and the crust, the inner part also called "flesh side".

The different types of leather by appearance and texture

Real or traditional leather

Leather is a material prepared from the skin of an animal. Each type of leather has its own characteristics (thickness, strength, feel, etc.).

full grain leather

Full grain leather is a leather that has kept its upper surface intact. It retains the natural grain and all the characteristics of the hide (suppleness, hold, strength), including roughness such as natural wrinkles, small scars or healed scratches. Full grain leather contains the epidermis and therefore the densest part of the fibres on the skin structure.

All Radermecker Tannery saddlery leathers are full grain leathers.

Full grain leather can have different finishes :

- Aniline finish: the application of a light, transparent coating, without altering the texture of the leather, more commonly known as aniline leather. Most Radermecker saddle leathers feature an aniline finish: Angel, Niagara shoulder, Niagara half-back, Boyoma half-back and Boyoma stretched.

- Semi-aniline finish: application of a combination of an aniline layer and a pigmented layer, slightly covering the hide. Radermecker saddle leather with a semi-aniline finish is the Gavarnie grained quarter leather.

- Pigmented finish: application of an opaque layer of pigment to completely cover the asperities of the leather, more commonly known as pigmented leather. Radermecker saddle leathers with a pigmented finish are Pykara dyed full grain leather.

Split leather

Split leather refers to the inner layer of the dermis, i.e. its "flesh side". It is obtained by splitting thick leather into two sheets. We offer Detian split leather.

Velvet-like leathers

Nubuck

This is a leather, usually from the cow, which is made from the outer surface of the hide, the grain. This material is then scraped or sanded to obtain a slightly rough effect with a few hairs. The very delicate sanding leaves some imperfections visible.

The sanding of the skin is only superficial, the highest quality skins are necessary. Indeed, if the skin has a stain, a scar or any other imperfection, sanding will not erase them. This treatment is light and leaves the grain of the leather visible.

Suede leather

Suede leather is a leather with a sanded surface. The appearance of the leather is reminiscent of velvet. Unlike nubuck, suede leather is obtained by using the hide on the inner surface side. It is also scraped and pinched but has a shorter pile than nubuck. Suede leather gives a velvety effect and a very pleasant feel to the material.

Suede leather

Both terms are actually approximations of language. They both refer to suede or nubuck. So when you hear the term "suede", it is often actually suede or nubuck.

Contrary to what one might think, "fallow deer" does not refer to the animal. Indeed, the animal has been a protected species for many years. The term "suede" is commonly used to designate leathers with a velvety appearance. The same applies to suede leather.

Special aspects of leather

- Vegetable leather: This is a shorthand term for vegetable tannedleather

- Crinkled leather: This is an undulation of the grain of the leather obtained by the retraction of the fibres of the flesh, essentially done on sheep skins.

- Aged leather: This is a surface shading that gives the leather a patinated appearance and is applied to calf, cow or sheep leather with a pigmented finish.

- Fat leather: This is a leather with an above-average oil quality, it is heavily nourished during tanning, it is a heavy leather that develops a patina over time.

At Radermecker Tannery, Niagara and Della saddle leathers are fed in a tallow bath (grease), they are called "suiffed leathers". This deep nourishment makes the leather easier to cut and work with, as well as more resistant to water. The tallow makes it possible to have a leather without maintenance because the fat is given in a constant way on the surface of the leather, giving it the necessary food and a beautiful patina. Suede leather is particularly resistant to the outdoor environment.

- Grained leather: This is a leather with a finish obtained by passing pieces of leather through a press. Depending on the "plates" or "moulds" of the press, different types of grain can be produced, such as the Pécari grain for our Gavarnie grained quarter leather.

- Drum's leather: This is a method of finishing leather that softens the hide and gives it a finely textured appearance, which is achieved by "stirring" the hides back and forth in a drum.

- Coated leather: This is a hide that has been coated or laminated with a film.

- Patent leather: This is leather with a thick layer of varnish applied to it, in order to obtain a glossy finish.

- Embossed leather: This is leather with a pattern recessed from the surface of the leather. This is the technique of repoussage, the embossing of a pattern on vegetable tanned leather. In order to highlight your design, the leather is embossed with various dies. Embossing consists of crushing the leather fibres around the lines of your design.

- Embossed leather: This is leather with a pattern in relief from the surface. This is the embossing technique which consists of transferring an existing pattern onto the leather by pressure. As with embossing, only vegetable tanned leather can be used for this cold technique. For all other types of leather, it will be necessary to resort to hot embossing which requires industrial heating presses.

- Openwork leather: This is a leather with parts cut out in a pattern, reminiscent of lace. The process is usually carried out by laser cutting on the whole or part of the leather.

- Stretch leather: This is a soft leather, usually lambskin, bonded to a stretchy cotton fabric.

- Boiled leather: This is leather that has been boiled in water to give it a certain hardness.

- Dip-dyed leather: This is leather dyed in the mass by immersion in a full bath dye, as opposed to surface-dyed leather. No other additional finishing is carried out. This so-called dipped finish is applied to different types of animal skins such as lamb, calf or kid.

- Nappa leather: This is a full grain leather treated to make it very supple and waterproof, so it is a fine, smooth and grainless leather. This so-called nappa finish can be applied to all types of animal skins and whatever the type of vegetable or mineral tanning.

- Double-sided leather: Also known as woolen or turned leather, this is sheep or lamb leather with the wool retained.

- Box calf: This is a chrome or chrome salt tanned calf leather with a smooth appearance, which is mainly used in the manufacture of shoes.

- Washed leather: This is leather that, once mounted and assembled, has been treated with water and enzymes to give it a lustrous, curled look and make it slightly stiffer. Washed leather has a vintage look. The so-called washed finish is mainly applied to lambskin.

- Basane: This is a vegetable-tanned sheepskin used for chaps in horse riding, the sort of gaiters that cover the legs of trekking riders or professionals (gardians, gauchos). It is also sometimes found as a lining for shoes.

- Pre-stretched leather: Frame-stretched leather with high resistance to elongation. Radermecker Boyoma Stretched Saddle Leather is a frame-stretched leather used to make stirrups and girth straps for horse saddles.

The origins of leather

Leather can come from different animal species: beef, buffalo, lamb, goat, sheep, calf, horse or foal, pig, cow or deer.

In addition to the different types of tanning and finishing applied to the hides, each animal origin has its own particularity, such as leather from beef, buffalo or cow will be a thick leather, mainly used in saddlery and furniture. Goat and calf leather are soft leathers used in saddlery, leather goods, decoration and fashion. Lambskin and sheepskin are soft and light and are more often used for clothing, and mainly for linings for leather goods.

Radermecker Tannery's saddle leathers are made from heavy oxen and bulls selected from responsible farms.

There are also exotic leathers which are commonly used in the luxury industry. In order to avoid any commercial abuses, their circulation is strongly regulated. Most of these exotic leathers come from farmed animals.

Exotic leathers are leathers that come from the skins of rarer animals.

Exotic leathers can be crocodile, snake, lizard, eel, shagreen (ray or shark), ostrich, etc.

Alternative materials

New alternative materials are being developed that attempt to mimic the mechanical and appearance qualities of leather. Many of the products available worldwide are marketed using terms such as 'vegan leather', 'vegan leather', 'fake leather', 'synthetic leather' or 'PU leather'. This means that they are made from artificial materials or alternatives to resemble the appearance of leather.

Synthetic or imitation "leather"

Synthetic "leather" or imitation is usually made with synthetic components such as PU (polyurethane), nylon, PVC, etc. to look like leather.

Imitation materials usually have a rubbery or "shiny" surface feel and a uniform appearance. They are cooler to the touch and often have a plastic smell. Many synthetic 'leathers' have a textile backing or intermediate layer, which can be seen on the cut edges. Synthetics burn more easily than leather, shrinking and curling with heat.

Many synthetics are printed with a leather grain effect or synthetic "leather" products are made to hide the cut edges. In this case, it is not always clear what is 'synthetic' leather, but in the EU and the US, brands have a responsibility to clearly label the materials used in the products they manufacture and sell.

In a growing number of countries, such as Brazil, Italy and Portugal, the term leather cannot be used in conjunction with synthetic materials at all.

Vegan "leather"

There is no such thing as vegan leather, or also called vegan leather. It is a marketing term used to describe materials (or imitations of leather) that are often plastic or derived from finished fossil fuels.

Much of this is derived from petroleum, a limited fossil fuel, as most commercial vegan leathers are made from plastics: PVC, Polyurethane, polyester, nylon, etc.

However, there are also products used to replicate the appearance of leather that come from alternative sources: grape skins, mushrooms, palm leaves, apples. To ensure the strength and utility of these materials, the vast majority are reinforced or mixed with synthetic resins and plastics.

The leathery appearance of "vegan leather" is only on the surface, as the artificial materials do not recreate the same fibrous qualities of leather that bind the layers together.

Reconstituted "leather"

Reconstituted leather is a material composed of leather fibres (leather scraps or crushed leather pieces) and binders (polyurethane, latex, acrylic, etc.). It is produced in rolls or sheets.

Reconstituted leather is produced from leather scraps and is a homogeneous material, economical and can be finished to look and feel like leather.

Remanufactured leather has been manufactured for over 70 years and is used as a material for footwear components, bindings, furniture elements, wall panels and leather goods.

The mechanical properties of composition leather are much lower than real leather, which is why it is usually used for non-moving parts.

Podcasts Dure à Cuir

Amélie Pichard launches the mini-podcast series "Dure à Cuir" to present and compare leather and its alternatives. In the continuity of her O.V.N.I (for Objets Valorisés Naturels ou Innovants) initiative aiming at informing the consumer about the materials currently used in the fashion industry and their limits, Amélie Pichard has produced a first series of 4 short format podcasts, entitled "Dure à Cuir". The objective remains the same: to encourage more transparency in an industry that is prone to confusion. Before a second season where she will dialogue with the actors of each sector, this first series of podcasts is now available here and can be shared without moderation.

Episode 1: Leather

This episode serves as an introduction and lays the foundations of this material. It explains the manufacturing process and begins to question the positives and negatives of its use.

Episode 2: Vegan leather

Here we question the interest or not of using alternatives to leather. The aim is to explain that choosing the animal cause by adopting vegan leather is to the detriment of the environmental cause.

At issue is the composition of alternative materials to traditional leather, which still rely heavily on plastic, when they do not require excessive use of water (e.g. cotton).

Episode 3: Vegetable leather

This is one of the biggest confusions in this field. For most people, vegetable leather = leaf, whereas it is only vegetable-based tanned leather. So let's take a look at this process and its differences from "traditional" chrome tanning.

Episode 4: The alternatives

This episode takes stock of the various innovative materials that Amélie has tested. In all transparency, she gives an overview of the pluses and minuses for each of them.